| Wärtsilä Engines | |||

| Wärtsilä 20 | Wärtsilä 22 | Wärtsilä 24 | Wärtsilä 26 |

| Wärtsilä 32 | Wärtsilä 34DF | Wärtsilä 38 | Wärtsilä 46 |

| Wärtsilä 50DF | Wärtsilä 64 | Wärtsilä L 20 | |

Bartech has been building a strong reputation for improving diesel engine reliability, safety and performance since it was formed in 1987. Almost immediately we began supporting major companies such as Shell, Lockhead and the OEM, Paxman Diesels, who relied on our specialist knowledge.

Fundamental to this growth has been the focus on our core beliefs of building long-term partnerships by sharing our expertise.

Even though our specialist diesel engineering services centre on engines, governors, turbochargers and fuel pipes, we constantly strive to enhance our support capabilities and develop our range of services.

Bartech has a strong team with varied specialised backgrounds including OEM training, CMM, machining, project management, quality, logistics, IT and administration which equips us to respond effectively and in a cost-efficient way to your specific requirements. These in-house skills are backed by the core company values reinforced by family ownership.

With most of Bartech’s early client’s coming from the marine industry, we have over 30 years experience in this sector and it’s thanks to these relationships we understand the increasing pressures Technical Superintendents, Chief Engineers, Operators and Crew are under and the problems unreliable propulsion and generator engines can cause.

In-depth sector knowledge

Our experience working with ship owners and managers gives us the ability to understand the challenges you face with tight schedules, potential contract penalties and rising costs, whilst conforming to the latest regulations issued by Lloyds and SOLAS to those issued by IMO, MCA, and other regulators.

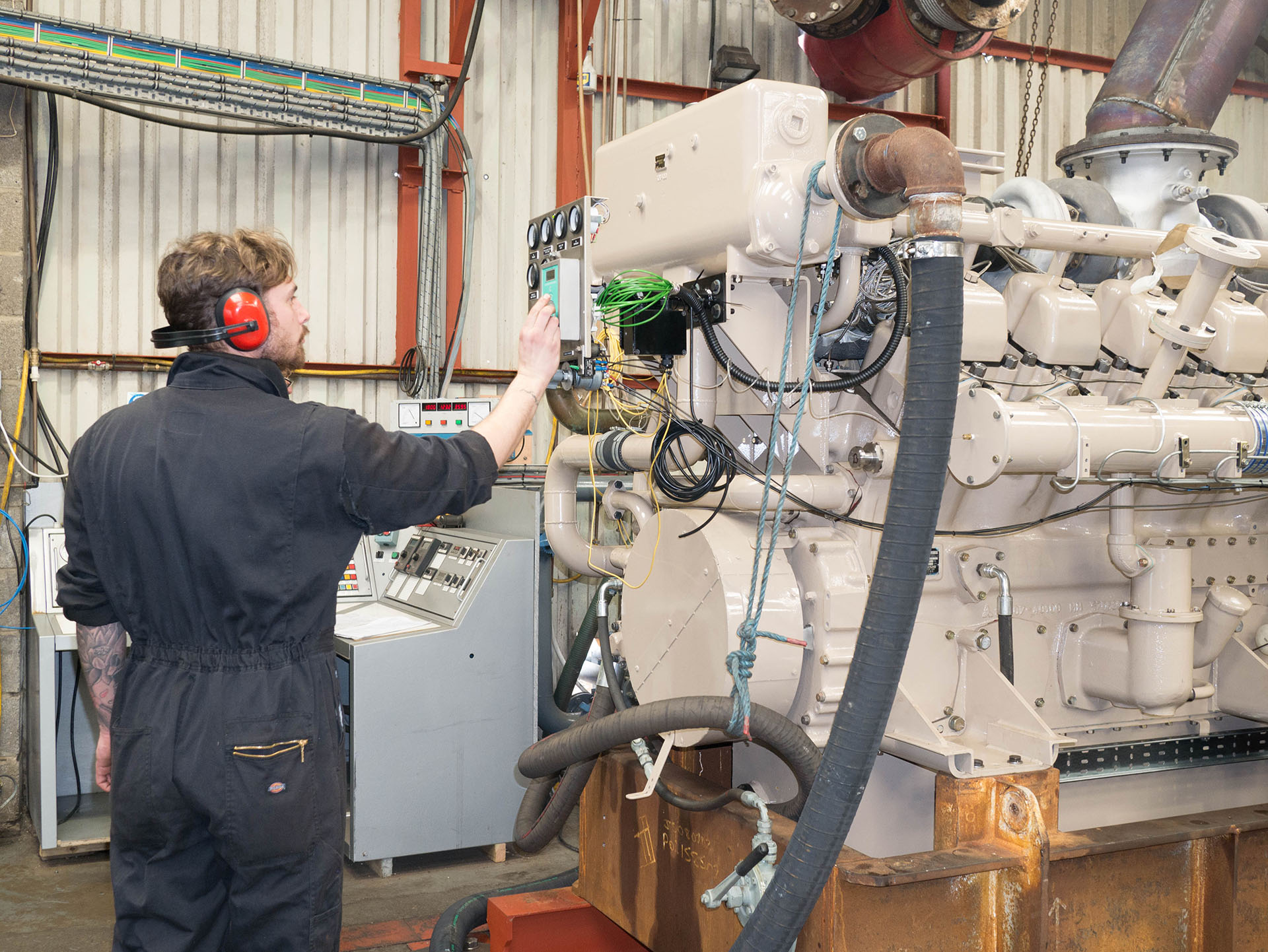

Experienced field service team

With our team of time served – highly trained and experienced engineers, we can be there when you need us, for breakdown responses 24/7 or scheduled maintenance worldwide.

Below are examples of the various projects we have carried out across the marine sector.

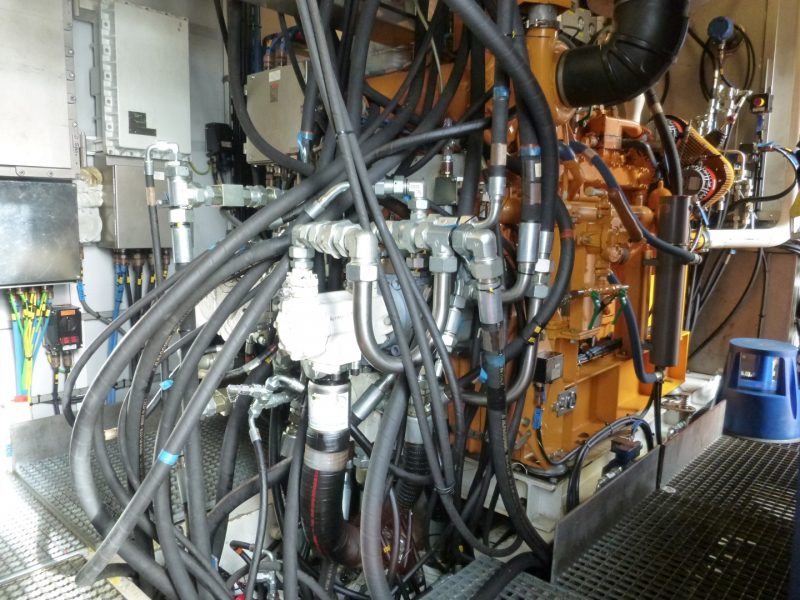

Offshore oil & gas companies need specialist support they can rely on to maintain and repair safety-critical equipment 24 hours a day. Health and safety are a priority and downtime an expensive consequence of breakdowns that is to be avoided at all costs.

In-depth sector knowledge

Our highly trained, dedicated offshore team offers complete 24-hour specialist support to our oil & gas clients worldwide.

We have the specific knowledge and engineering expertise needed to ensure that even the oldest of engines and equipment can be restored to working order quickly in the event of breakdowns, and can be kept well maintained to avoid costly future disruption.

Supported by our Aberdeen based Technical Service Manager, our offshore team of diesel engine experts will respond to breakdowns rapidly, day or night to get your engines and equipment safely back up and running as quickly as possible.

The complete service

You also get our full, bespoke, proactive support service, which includes audits, surveys and planned maintenance to ensure maximum operational effectiveness for your engines, whether they are used in fire pump, emergency generator, starter, crane, or lifeboat applications.

Having worked with Shell for over 25 years and now supporting over 20 oil & gas companies, our expertise, dedication, innovative problem solving and reputation for fast, reliable breakdown response is second to none.

Our focus on proactive maintenance enables us to provide you with engineering solutions that minimise disruption, with detailed backup, documentation and a commitment to the highest levels of health and safety as standard.

If you’re looking for generator maintenance, Bartech’s team of experienced engineer’s will ensure your critical engine is well looked after, giving you the peace of mind that comes with expert engineers, full documentation and our 12-month warranty.

Generator experts

At Bartech, we’re on a mission to help businesses like yours to enjoy the peace of mind that comes when you know back-up power will deliver if needed. That’s why we provide an expert generator maintenance service to ensure that our clients get what they need to keep their organisations going.

Peace of mind

Decades of expertise in maintaining emergency and standby generators combined with our membership of AMPS (The Association of Manufacturers of Power generating Systems) ensure we can help you get that peace of mind that comes when you know that everything’s looked after and running smoothly.

AMPS is the trade association and industry voice for the UK’s world-leading diesel and gas-engine power generating sector and associated businesses.

Complete Support

If you have the responsibility of the generator as an owner, through a facility management company, or even a generator contract, we can bring our 30+ years of engine expertise to reduce costs and problems caused by power issues.

Over time we have seen more than most how the little things can cause huge expense and inconvenience

Our generator maintenance team will provide you with:

Emergency breakdown response from specialised engineers 24/7

Technical support from engineers with specialist experience and OEM training

Full documentation for complete trace-ability and historical records

Safe working practices with full RAMS compliant with our OHSAS 18001 accreditation

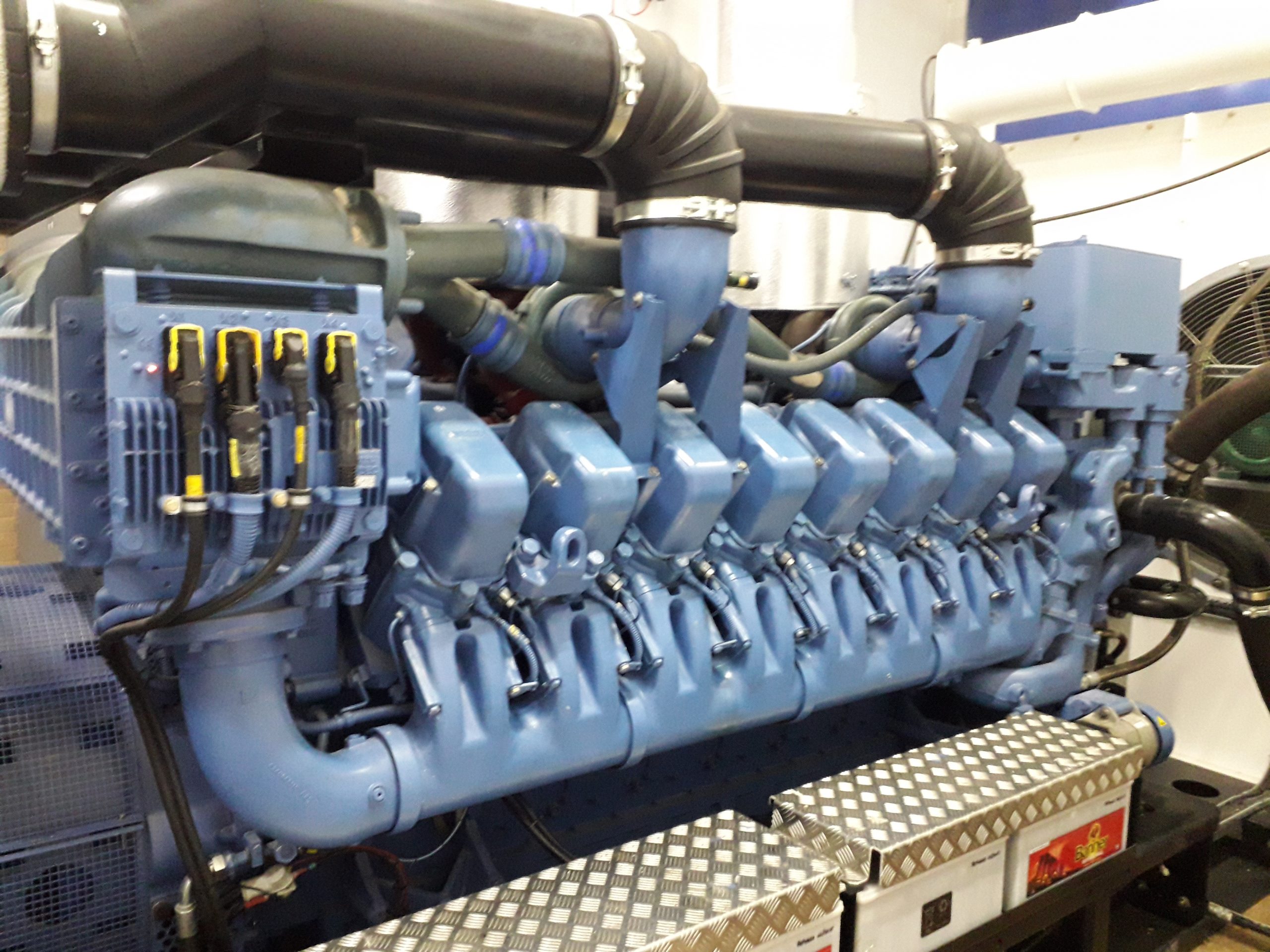

How we can help you with your Wärtsilä engines...

Specialist independent Wärtsilä expertise for all your engine servicing, overhauls and support.

With Wärtsilä trained and experienced engineers, we can supply the parts and the skills to offer complete Wärtsilä engine services, from routine maintenance to full Wärtsilä engine repair and overhauls.

The complete solution

As an experienced, independent Wärtsilä engine specialist we can offer you more solutions and alternatives for your Wärtsilä engine repair, overhaul, maintenance and spares.

In short, however you need help with your Wärtsilä engine, we’ve got the skills, the contacts and expertise to help you, often with a significant saving to be had.

If you’re after a trustworthy Wärtsilä engine specialist with an excellent track record for your job then let's get started

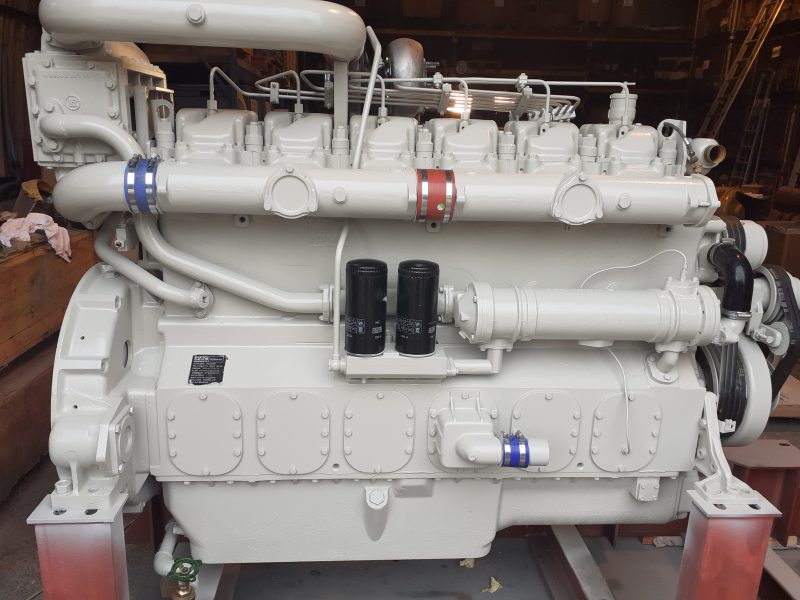

What we can do for your Wärtsilä engine:

Identify and source the right parts for you, either from the original manufacturers or other engine manufacturers, all with a 12-month warranty.

Access our large inventory of spares to get you the right piece of equipment

Supply and install Wärtsilä engines for you, new or reconditioned.

We can help you with major assemblies

Our engineers (who work directly for Bartech) can visit you onsite (both offshore and onshore) to help with overhauls, fault diagnosis, commissioning and alignments

You’ll get a 12-month warranty with all parts supply and work completed

How you can benefit from our expertise:

Reduced parts costs by purchasing directly from manufacturers

Access overhaul and engineering solutions, with big savings to be had when compared with replacement options

You’ll be tapping into the expertise of highly experienced and Wärtsilä trained service engineers who can utilise engine knowledge from other makes to solve your problems quicker

Use us to source genuine spares for out of production models from worldwide stockists

Get measurement and test sheets with reconditioned parts and assemblies, giving you the peace of mind that comes from knowing your engine is in the best possible shape.

| Wärtsilä Engines | |||

| Wärtsilä 20 | Wärtsilä 22 | Wärtsilä 24 | Wärtsilä 26 |

| Wärtsilä 32 | Wärtsilä 34DF | Wärtsilä 38 | Wärtsilä 46 |

| Wärtsilä 50DF | Wärtsilä 64 | Wärtsilä L 20 | |

Bartech cover the use of engines in many applications such as Locomotive, Fire Pumps, Cranes and Agricultural, with the same level of support, parts supply and highly experienced engine specialists.

Our engine expertise goes beyond working in the oil & gas, marine and generation sectors.

Locomotive engines

Fire Pump driver engines

Crane engines

Agricultural engines

Locomotives

Case Study: Sulzer Governor - Locomotive Application

Bartech was invited to dismantle and inspect the Sulzer governor and report any findings. Click here for the case study to see what we found and how it was rectified for the operator.

Case Study: ABB VTC254 Replacement - Locomotive Application

Bartech was invited to source 4 off VTC254 Turbochargers to be installed on their 16V280ZJA diesel-electric prime locomotive mover. Click here for the case study.

Cranes

Case Study: 12-month service to offshore platform's Cummins NTA855-C-360 Crane engine.

Bartech was invited to carry out a 12-month service to the crane engine.

Fire Pumps

Case Study: Deutz DFP6 1013 C20 Firepump RCA

Bartech was invited to carry out an RCA on an offshore operator's Deutz DFP6 1013 C20 Firepump engine.

Coolant Engines

Case Study: Investigation of an oil leak at turbine end of the Holset 4MF turbocharger on the coolant engine

This HP BUCS coolant engine's turbocharger was sent to our Colchester workshop so we could Investigate reports of an oil leak at the turbine end of the turbocharger.